By Carl Hohman

WHAT IS A DIAMOND BLADE?

Some people who think of a power saw may picture a tool with a metal blade that has sharp teeth cutting through a piece of lumber or metal. However, there are a large variety of power saws, many of which run diamond blades, which don't have sharp teeth at all. Diamonds are the hardest natural mineral known to man so using them to cut the hardest materials in the world only makes sense. The most common materials diamond blades are used to cut through in the construction industry are concrete, brick, pavers, stone, and asphalt. They also come in a variety of shapes and sizes including core bits for cutting holes, grinding wheels for surface grinding and blades for regular cutting.

WHAT MAKES A DIAMOND BLADE?

There are four components of a diamond blade: diamond crystals, metal bond, diamond segment, and a steel core. The diamond crystals are typically synthetic rather than natural. Cutting performance is determined by the type, shape, and size of these diamond crystals, which are held in place by a mixture of various metals. This combination is often referred to as a ‘diamond segment.’ This metal bond regulates the rate at which the diamond crystals are exposed, thus determining the speed of cuts and length of life for the blade. The diamond segment, when attached to the blade, is wider than the blade’s core to reduce drag on the blade and decrease the chance of the blade binding within the material being cut.

HOW DO DIAMOND BLADES WORK?

Unlike most other saw blades, diamond blades don’t actually cut material. Instead, they use friction created between the diamond segment and the material being cut to work like a grinding wheel. When cutting hard materials as mentioned earlier, each tiny diamond particle scratches the material as it spins around the blade. In just seconds, millions of these tiny particles have made millions of little scratches that eventually go all the way through the material. When cutting a piece of hard material with diamond a blade, technically no cutting has occurred at all. That’s why diamond blades don’t need to have sharp teeth like other saw blades.

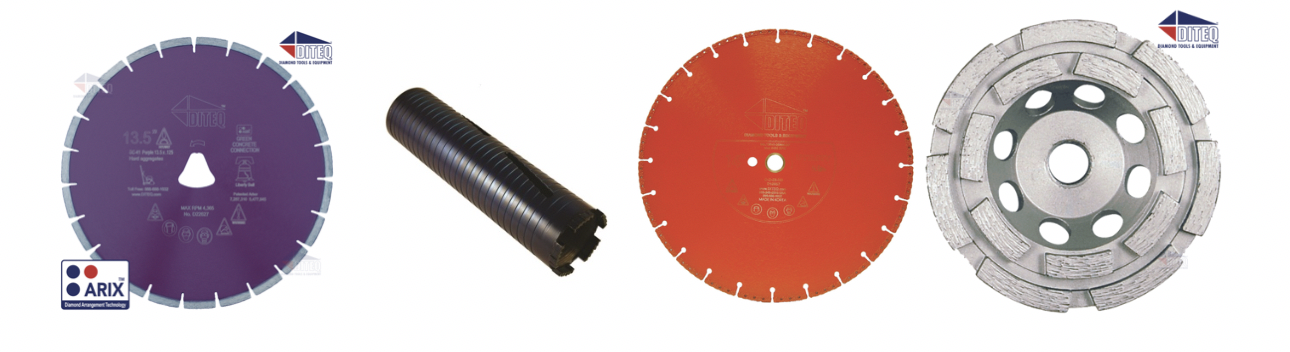

DITEQ GUARDIAN BLADE

At Outpost, we highly recommend the Diteq Guardian Blade for your all-purpose, the best bang for your buck blade. Why go out and buy 5 blades when one blade will do it all and last longer than anything in the industry? The Guardian Blade can be used for cutting concrete, reinforced concrete, brick, pavers, stone and asphalt (check out the video to prove it here) and comes in 12” to 20” diameters. It can be used with high-speed hand saws, masonry saws, brick, and block saws or walk behind saws up to 20 horsepower and can be used either wet or dry. The Guardian blade features ARIX diamond arrangement technology, which aligns diamonds in their bond, for faster-cutting speed and longer blade life.

Diteq guarantees the Guardian blade will cut 30% faster and have a longer blade life (up to double the industry average) of any blade you’ve ever used. To back it up, Diteq offers a no-risk guarantee to our customers. If it’s not the best blade you’ve ever used, you get your money back, no questions asked. Give it a shot, you’ve got nothing to lose!

Related Videos

.png&width=880&height=0)