Dobie Cement Support Blocks

By Darin Williams

Concrete is strong…kinda. It has great compression strength (able to bear compressing forces), but very little tensile strength (able to bear pulling or bending forces). This will result in a concrete slab inevitably cracking somewhere. It is false economy to rely on a concrete-only project to stand up to the stresses of use and time – it needs some kind of “bones.” Steel has great tension-resisting strength, but steel is very expensive compared to concrete. Strategically-placed steel (or even fiberglass) reinforcing bars (aka rebar) are laid in place before a concrete pour to provide the additional tensile support to strengthen the concrete as it adheres together into a solid unit. This rebar and concrete combination is called “reinforced concrete.” Sometimes, there’s a LOT of reinforcement…

Proper placement of rebar within concrete is essential for giving the concrete the right support and strength in the right places, allowing the steel bars to absorb the tensile loading. For best results, rebar is generally located at the center or slightly above the center of a concrete slab. Instead of “placing” or inserting the rebar during a concrete pour, the rebar is prepared at the proper location and height, then the concrete is poured under, around, and over the rebar to embed it in the slab.

To position the rebar at the proper location prior to the concrete pour, some kind of support is most often used to keep the rebar in the right place. You could just have someone hold the rebar in place, but, well, that might lead to long-term problems.

While something as simple as a stone or brick could work for the rebar to just lay on, an aggressive and heavy concrete pour moving in and around the rebar during installation could topple or move these expedient support methods. Therefore, professionals typically use something more intentional to keep rebar from falling or getting misplaced during a pour which would otherwise render the rebar strength ineffective in supporting the concrete in the right places. These supports are called “chairs” and may be made of metal or plastic or other non-corrosive material. In fact, a great ready-to-use solution is made from a small concrete block called a “dobie.”

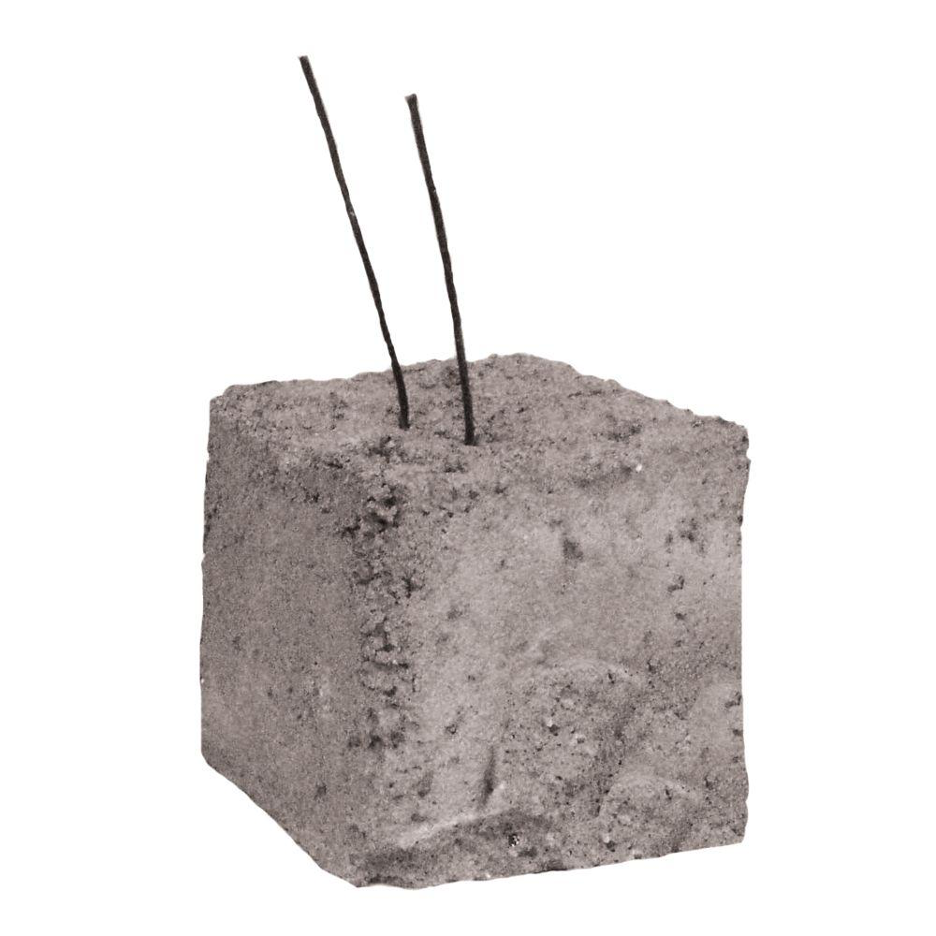

While dobies are available in multiple sizes for various height and placement requirements, a common size dobie is 3” x 3” x 3”. To prevent rebar misplacement and hold the rebar at the required height, two 16-guage wires embedded in the dobies can secure rebar sticks or welded wire (such as wire mesh, a concrete-strengthening alternative to rebar) along the run of the rebar (or wire) and/or at intersections, as seen in this video:

Here at Outpost Construction Supply, we provide these dobies for just such installation needs. The dobies come in rows of 6 which are easily broken apart along scored lines for individual dobie placement.

Contact your field rep or Outpost Construction Supply directly for answers to your questions and to schedule your delivery of dobies to your concrete project!