Pouring Concrete

By Alex Watrud

Pouring Concrete

Concrete pouring is a crucial process in general construction. Pouring concrete can be both easy and fun, but can also be very difficult. Without the correct methods being used and considerable focus and concentration being applied, it can end in an expensive disaster. The following information explores some of the different methods used to pour concrete. It also provides some precautions to be aware of during the process.

Columns and Walls

When pouring concrete into tall walls or columns, it is recommended that the concrete be placed in layers. These layers should be anywhere between 12” to 36” thick. The pour should include an interval of time between each layer to allow for settling and pressure distribution. Depending on the environmental temperatures, this interval should be around 20-30 minutes, using shorter intervals for hotter air temperatures. Also, each layer should be compacted with a vibrator to ensure even distribution and eliminate layer seams. To avoid batch separation, ensure the concrete is poured straight down into forms and does not bounce or deflect off the inner faces of the form at an angle. This will keep the bottom of poured walls and columns from segregation and honeycomb formations.

Slabs

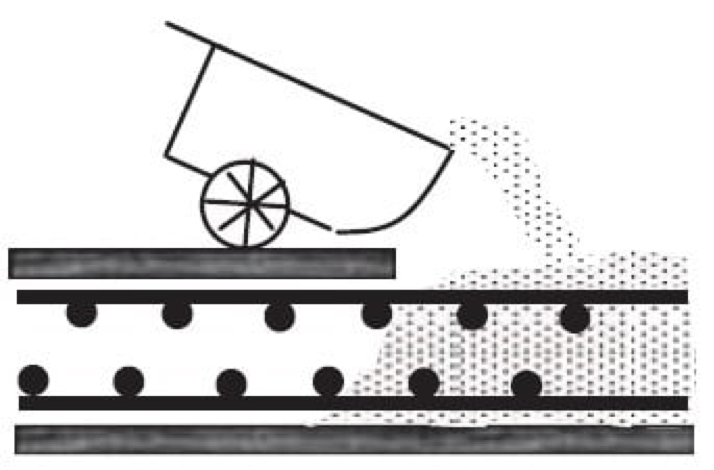

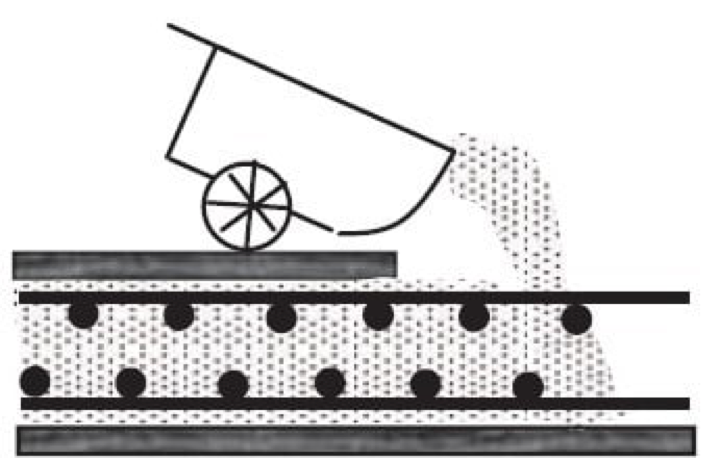

When pouring concrete slabs, the most generally recommended practice is to pour concrete into the face of existing concrete, and not away from it. The figures below demonstrate the proper (figure 1) and improper (figure 2) methods of pouring a concrete slab.

Figure 1

Figure 1

Figure 2

Inclines

In most instances, pouring concrete on inclined surfaces is more challenging compared to flat slab surfaces, and, as such, needs more effort to avoid segregation. Using a baffle at the end of a chute or dump bucket as the concrete is placed is the best way to get the concrete to stay on the slope and avoid batch separation and aggregate build-up at the base of the incline.

Using Pumps

As concrete pumps have become more readily available, the industry has seen a large increase in pump usage in comparison to conventional pouring methods. Using a concrete pump is one of the easiest and most commonly used methods to pour concrete. When using a pump, it is best to ensure that the pump hose nozzle is as close as possible to the final concrete position. This will eliminate much of the batch segregation and any other undesired effects. Utilizing concrete pumps also allows for concrete placement in locations that may be more inaccessible using traditional pouring equipment.

For all of your concrete accessory needs including forming, chemicals and tools, check out the concrete and concrete accessories sections at outpostcs.com.