By Holly Kirkwood

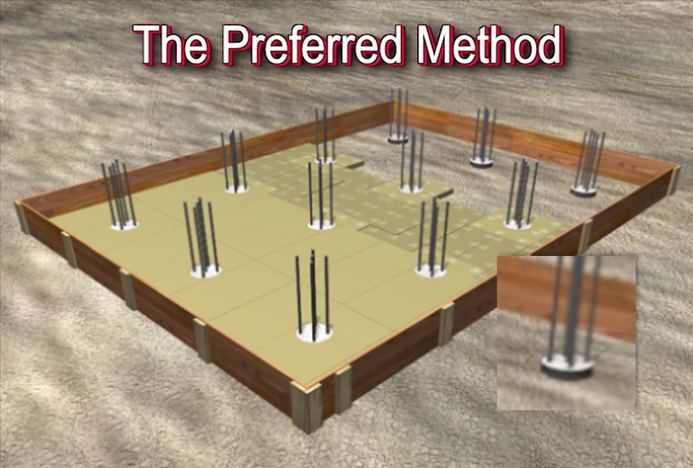

The ground is constantly expanding and swelling, especially in Colorado. Rapid shifts in temperature can add to the challenge of pouring concrete correctly. Once cured, concrete will expand and contract with hot or cold temperatures. “Void forms” or “carton forms” are a product created by SureVoid made from paper construction products to create space between concrete structures and expansive soils.

What is it?

SureVoid helps isolate concrete from the swelling ground. Its uses are two-fold, each important to its role in helping concrete placement. SureVoid allows for concrete to hold its form while drying until the support beams or structural slabs can support themselves. While supporting the drying concrete, it also absorbs moisture from the ground, gradually losing its strength, allowing the soil to expand without causing any damage!

SureVoid is a trusted brand designed to sustain almost any concrete load and configured specifically to the needs of your pour. Outpost can take care of your custom needs. SureVoid is truly amazing because it can withstand pressure up to 35’ liquid-head walls and structural slabs up to 13’ in thickness (voidform.com). After days of setting, it begins to lose its form due to the absorption of moisture as concrete is curing, thus no longer needing the support of the product. SureVoid products are “comprised of corrugated papers of different strengths and flutes, bonded together with white, water-based adhesive or held in place with staples (voidform.com).” These materials allow for it to weaken as it absorbs water creating the needed space between concrete form and soil. Void forms are easy to install, lightweight, and can be assembled for on-site convenience. They are also a cost-efficient solution to protecting your concrete pour.

Below are a few recommendations from VoidForm when it comes to installation of the product itself:

1. Keep void forms dry at all times prior to concrete placement.

2. Prepare grade to an even and smooth surface around the drilled pier.

3. Use the recommended hardboard on the entire surface to prevent immediate water or concrete silt penetration and pinpoint loading during construction.

4. Place concrete.

To help better assist in figuring out your needs on your project, VoidForm has provided a product questionnaire. Click Here.

.png&width=880&height=0)